The FLEX flameless explosion venting device is a suitable solution for installation on technological equipment inside buildings or in production halls. Unlike conventional explosion venting, where temperatures up to 1 500 °C can be achieved, the FLEX device can cool the flame and flue gas temperatures to a level that is no longer dangerous for technology and the people around the equipment. FLEX meets the strictest requirements of the legislation for flameless venting and is certified according to EN 16009.

Benefits & Application

- dust class St1 / St2 / St3

- recommended for facilities with metallic and non-metallic dust, including melting, fibrous and coarse-grained dust

- extremely low MIE, MIT

- effective flame and temperature capture

- suitable for technologies with higher hygiene requirements

- use in outdoor and outside zone · possibility of curved design

- minimum safety zone requirements to better facilitate the movement of personnel

- suitable for vertical conveyors

- standardly equipped with an explosion venting device with an opening indicator

Two Function of FLEX Flameless Explosion

Explosion venting and prevention of fire propagation into free space are two basic functions of the device.

The explosion venting device opens due to fast increasing pressure and the FLEX absorbs flame, burning dust, and gases. As opposed to an explosion venting the FLEX device is capable to absorb these undesirable effects thanks to its construction.

The explosion venting can achieve temperatures up to 1 500 °C, with light metals such as aluminum and magnesium the temperature being around 3 000 °C. During explosion venting with the FLEX flameless equipment, the temperature is lowered to a safe level that is not dangerous for surrounding equipment and for work and movement of personnel.

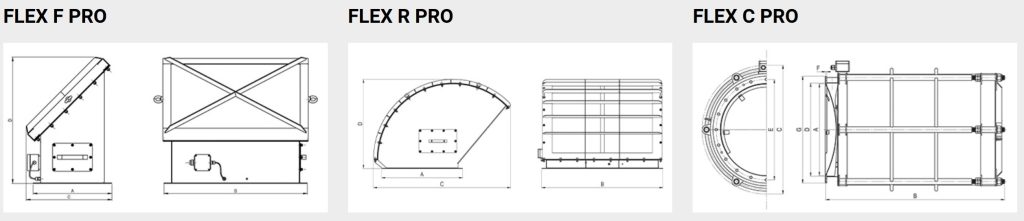

FLEX Devices Types

Contact : 099-017-7779

Email : oel_engineer@outlook.com

Line ID : santithep_s