Ensure your food production process meets safety standards and prevent costly production interruptions and product recalls with our comprehensive consultation service and bespoke design and product manufacture. We can examine your production process and advise on the strategic locations for magnetic separation equipment, to remove larger contaminants such as nuts, bolts and screws, as well as ferrous particles and tiny paramagnetic particles such as stainless steel scrapings from worn equipment.

Remove Contaminants From Food Products

A magnetic trap in food processing uses powerful magnets, often rare earth magnets, to capture ferrous metal contaminants from food products, protecting consumers from metal fragments and preventing damage to processing equipment. The process involves installing magnetic separators, such as bar or grate magnets, into the product flow of liquids or powders, where they attract and hold metal particles like nuts, bolts, or fine dust. This purification step ensures food safety, meets regulatory requirements, and improves product purity.

Types of Magnetic Traps

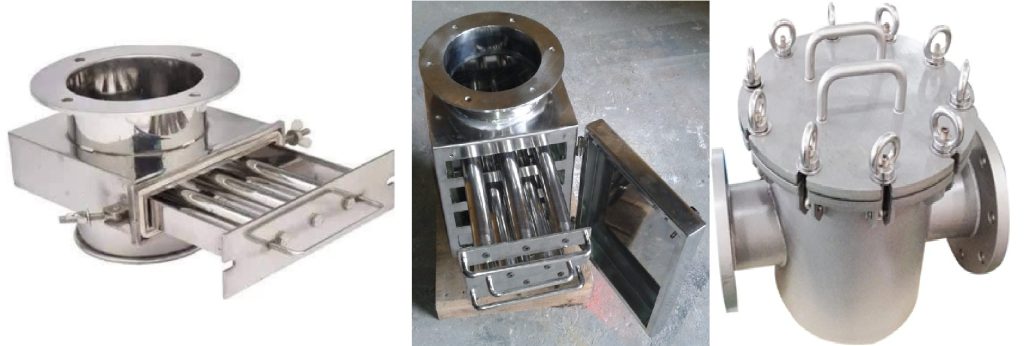

- Magnetic Drawer Traps: Designed for dry products, these traps use magnetic bars or grates to remove contaminants from flowing powders or granules. Foreign bodies, typically metallic parts like bolds, screws or just some metal shavings, can be detrimental to the process, by damaging (rotating) equipment, or to the final product. Implementing magnetic separation at different points of the process is an efficient solution to detect the presence of a metallic foreign body, remove it, or at least isolate a production suspected with contamination. Magnetic traps for food industry for instance, are very important to make sure no metal foreign body can be found by the end consumer, which could be a food safety hazard.

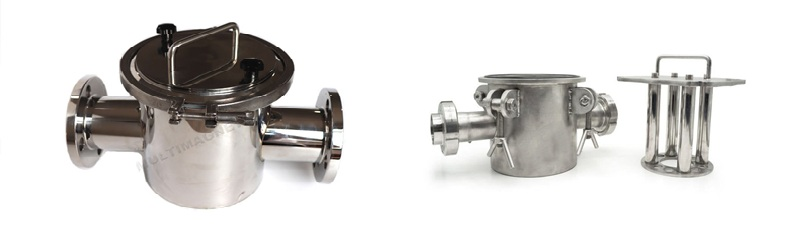

- Magnetic Liquid Traps: These are used for liquids, like sauces or juices, and often use powerful bar magnets inside a housing designed to withstand corrosive environments. It removes ferromagnetic particles, keep the material metal-free, and protect downstream equipment. These traps typically consist of a stainless steel housing that encases a series of high-strength magnetic elements, such as neodymium (NdFeB) or rare-earth magnets. The housing features an inlet and outlet for liquid flow, and the magnetic elements are arranged in a grid or tube configuration to maximize contact with the liquid stream.

- Suspended Magnets: These hang above conveyor belts, capturing larger metal fragments from materials as they pass underneath. It is designed to remove damaging tramp metals (ferrous/iron) from conveyed materials. These magnets improve product purity and protect downstream crushers, mills, pulverizers and grinders, and remove sharp metal that can damage or tear expensive conveyor belts.

++ Key benefit

- Food Safety: Removes dangerous metal contaminants, protecting consumers from foreign objects in food products.

- Equipment Protection: Prevents damage to processing machinery, such as crushers and other equipment, from metal fragments.

- Regulatory Compliance: Helps food manufacturers meet food safety regulations like the FDA’s Preventive Controls for Human Food program.

- Product Purity: Enhances product quality by ensuring that finished products are free of metal impurities.

Contact : 099-017-7779

Email : oel_engineer@outlook.com

Line ID : santithep_s